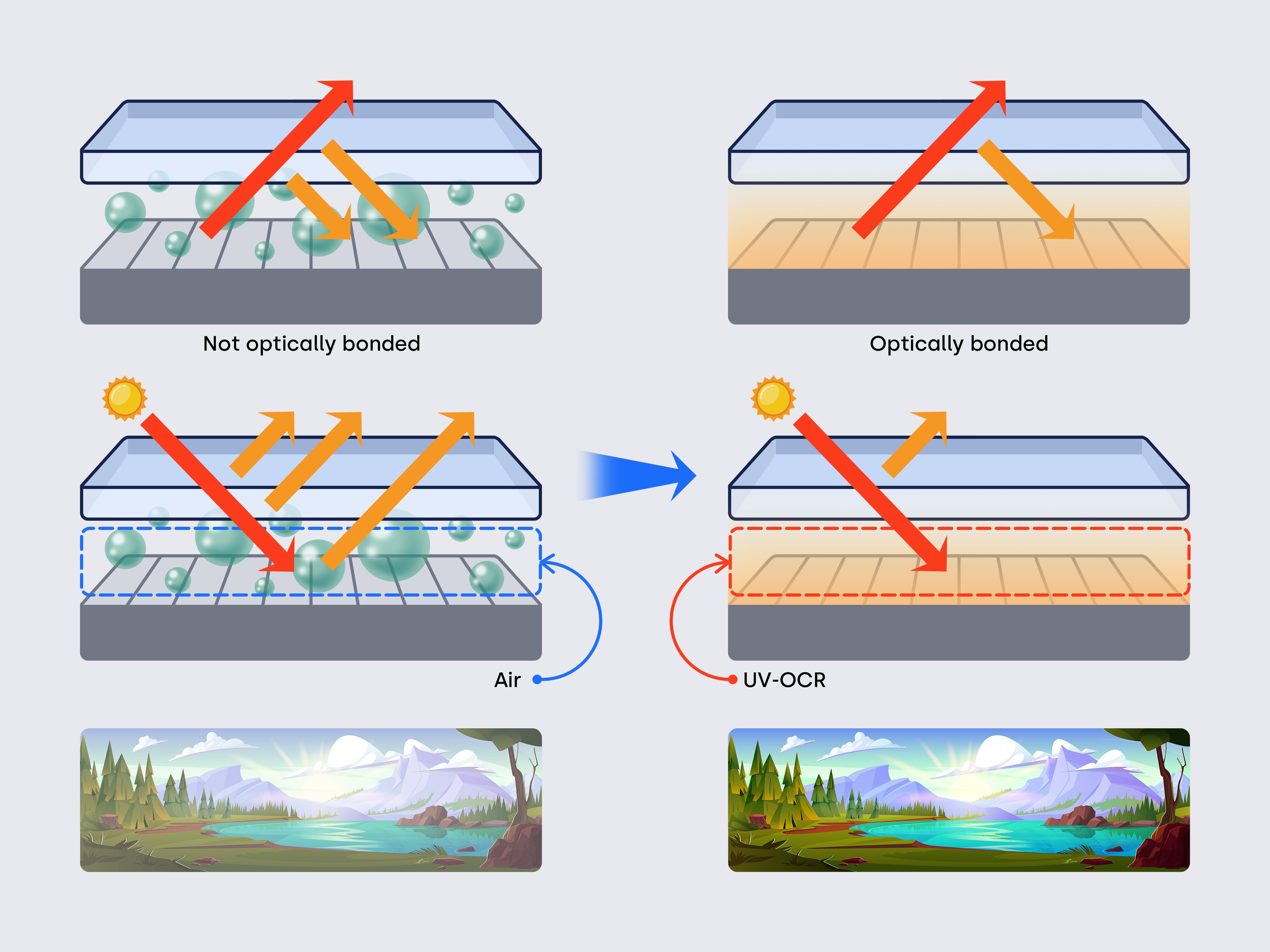

Bonding explains why some displays remain readable outdoors while others suffer from heavy glare. It is why screens in humid environments can develop cloudy spots over time, and why dust may accumulate behind the glass in dusty surroundings. But what exactly is bonding, and what impact does it have on performance?

What is Display Bonding?

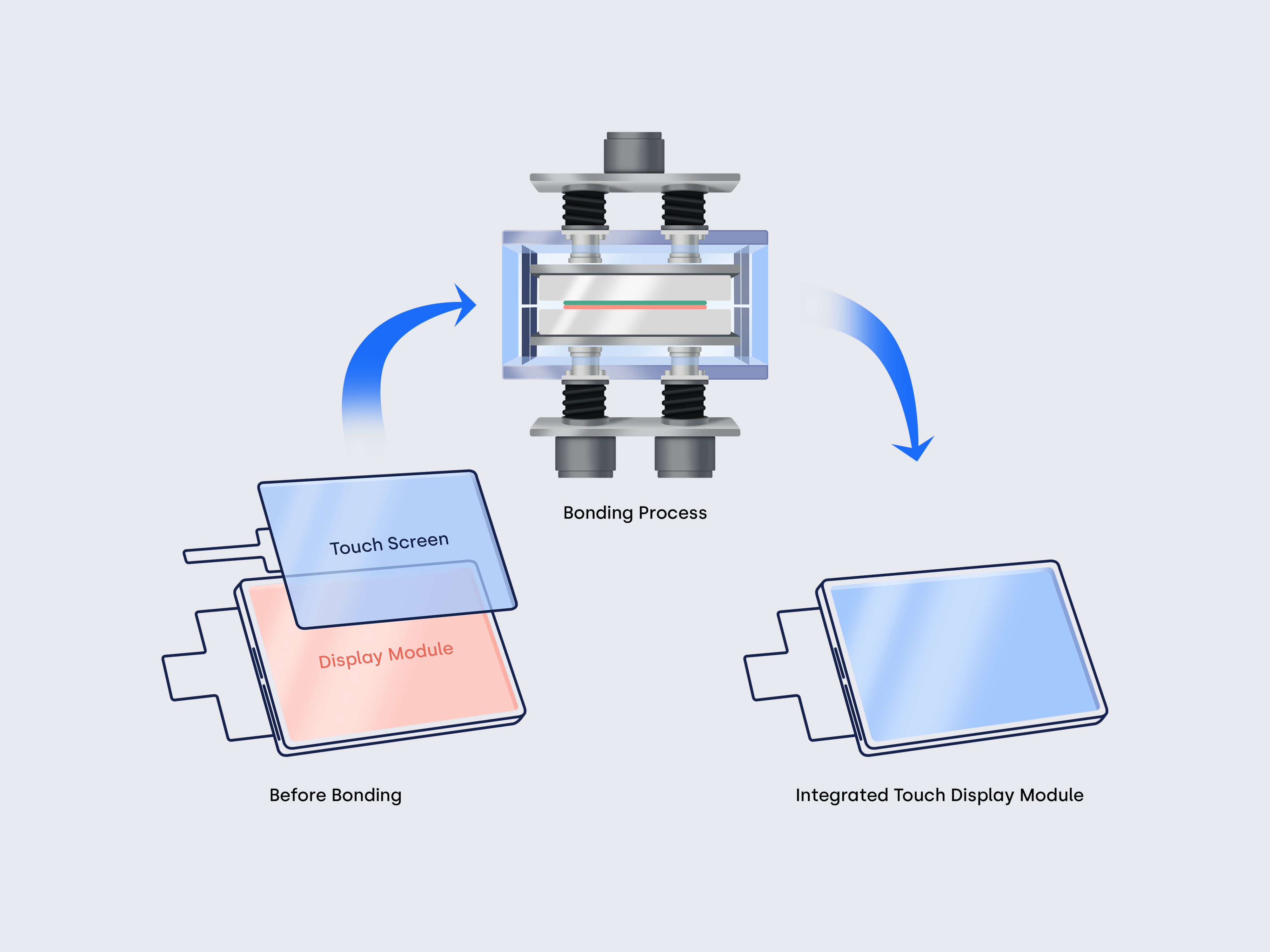

To understand bonding, it is important to first recognize that a display is not a single piece of glass. It is built from multiple layers. At the base is the LCD panel that generates the image. Above that sits a protective cover layer, most often glass but in some cases a transparent plastic or composite material, designed to guard against scratches and impact. In the case of touchscreens, an additional touch-sensitive layer is added. These layers are not simply stacked on top of each other. They must be mounted together during the production process, and bonding refers to the method used to connect them.

Bonding is a highly precise process. The layers must be both optically aligned and mechanically stable, which requires careful materials and techniques. Manufacturers use different bonding methods depending on cost, performance requirements, and environmental conditions. The method chosen directly affects how the display looks, feels, and performs in real-world use. Broadly speaking, three main bonding methods are used in display manufacturing. Each takes a different approach to how the cover layer is attached to the LCD, and each comes with its own strengths and weaknesses.

Bonding Methods

Air Gap (No Bonding)

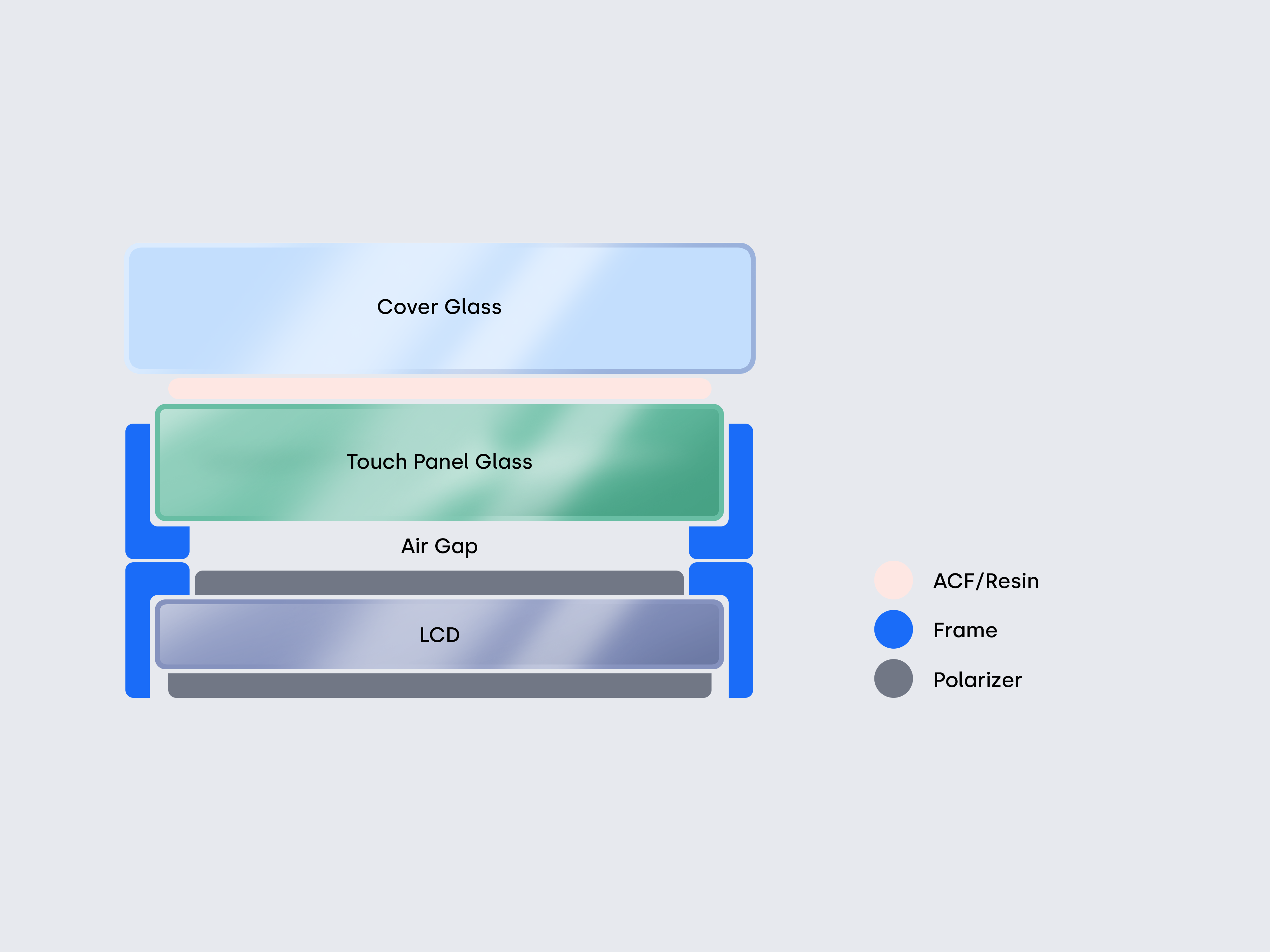

In the simplest construction, the cover layer is mounted above the LCD with only a thin frame or adhesive applied at the edges, leaving a small air gap in between. This approach is inexpensive and easy to manufacture or repair, but it also leads to strong internal reflections, reduced readability in bright conditions, and a higher risk of condensation or dust ingress. Since only the edges are fixed and no adhesive fills the gap, this is not considered true bonding. Because of the low cost, it remains the most common method in consumer devices.

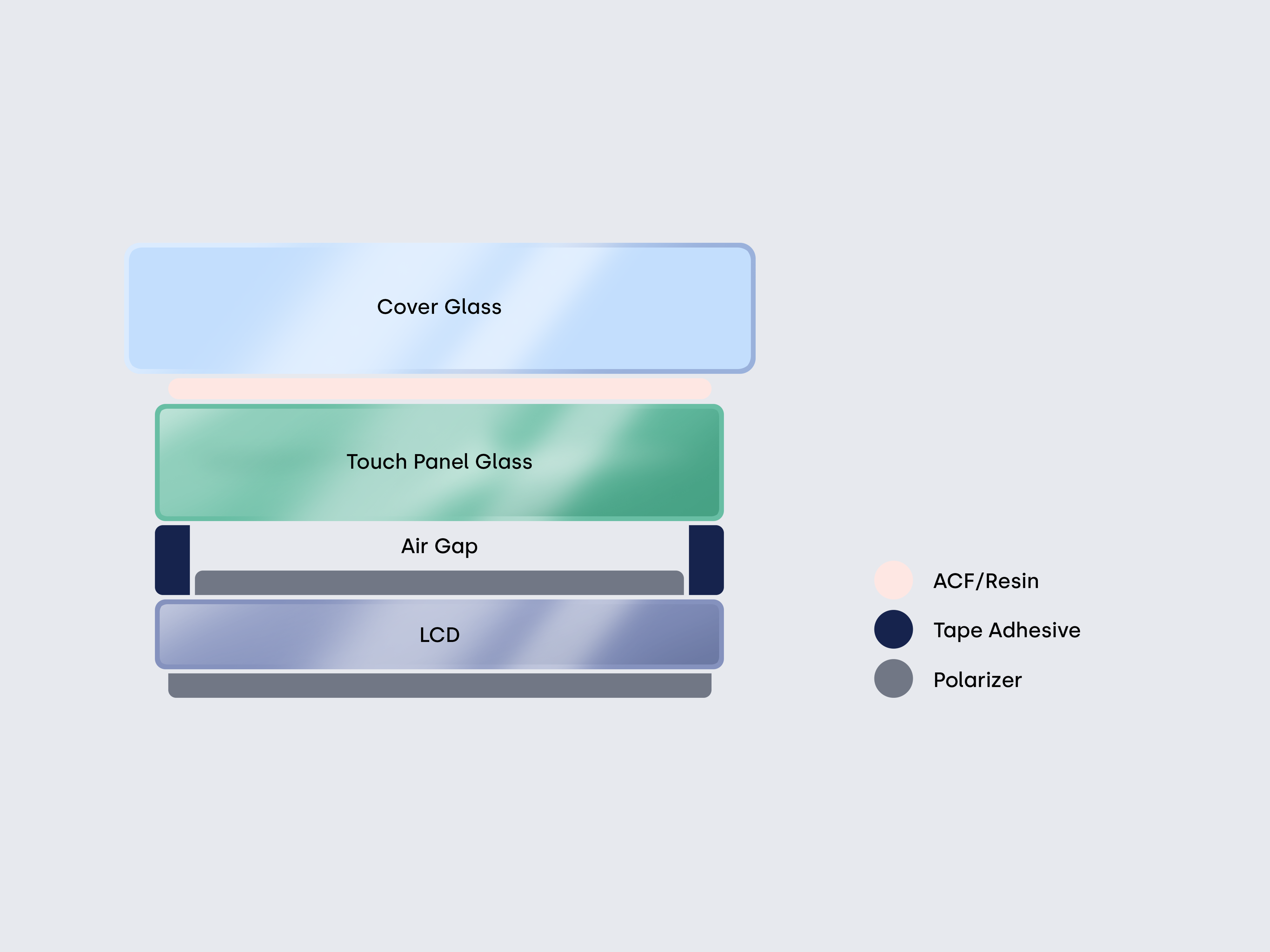

Tape Bonding (Edge Bonding)

In this method, double-sided adhesive tape is applied around the perimeter to fix the cover layer to the LCD. It is more robust than a simple air gap and offers better sealing against dust. However, the central gap remains, so optical performance is still limited. The reliability of tape bonding depends heavily on the type and quality of adhesive used. Lower-grade adhesives can degrade over time, especially in environments with high humidity or large temperature variations. In extreme cases, this can cause the cover layer to loosen or detach from the LCD. For that reason, tape bonding is mainly chosen as a cost-driven solution, suitable for less demanding conditions where long-term stability is not the highest priority.

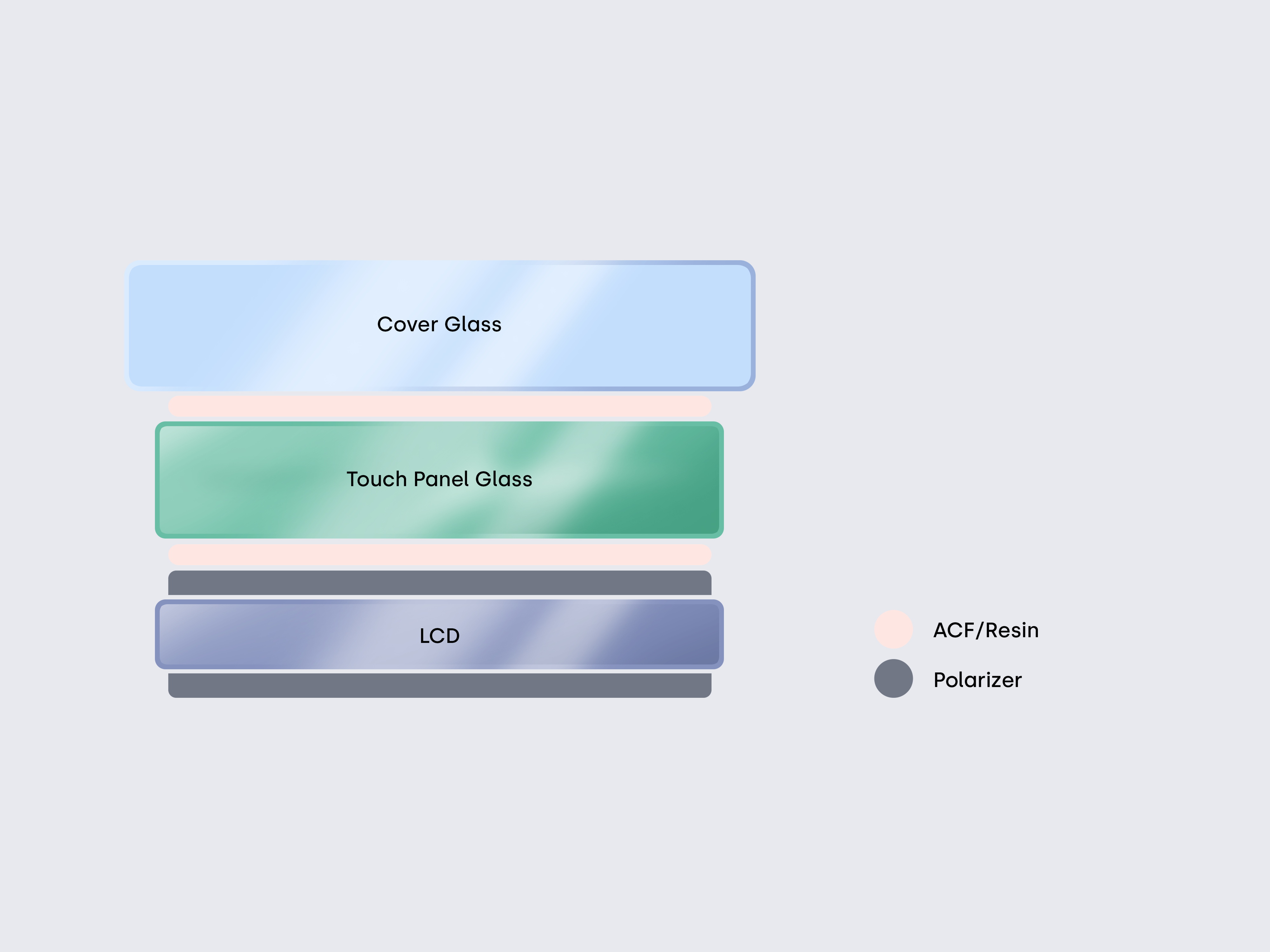

Optical Bonding (Full Lamination)

For professional use, optical bonding, also known as full lamination, is considered the most effective technique. In this method, the entire space between the LCD and the cover layer is filled with a transparent adhesive such as silicone, epoxy, or polyurethane. Once cured, the adhesive creates a solid, uniform bond that eliminates internal reflections, improves visibility in bright environments, prevents dust and moisture ingress, and strengthens the overall mechanical structure of the display. Because of these advantages, optical bonding has become the preferred technique for demanding environments. Within this category, however, different approaches exist.

Optical Bonding Techniques

Within optical bonding, two main techniques are used: OCA (Optically Clear Adhesive) and OCR (Optically Clear Resin). Both eliminate the air gap, but they differ in how the adhesive is applied.

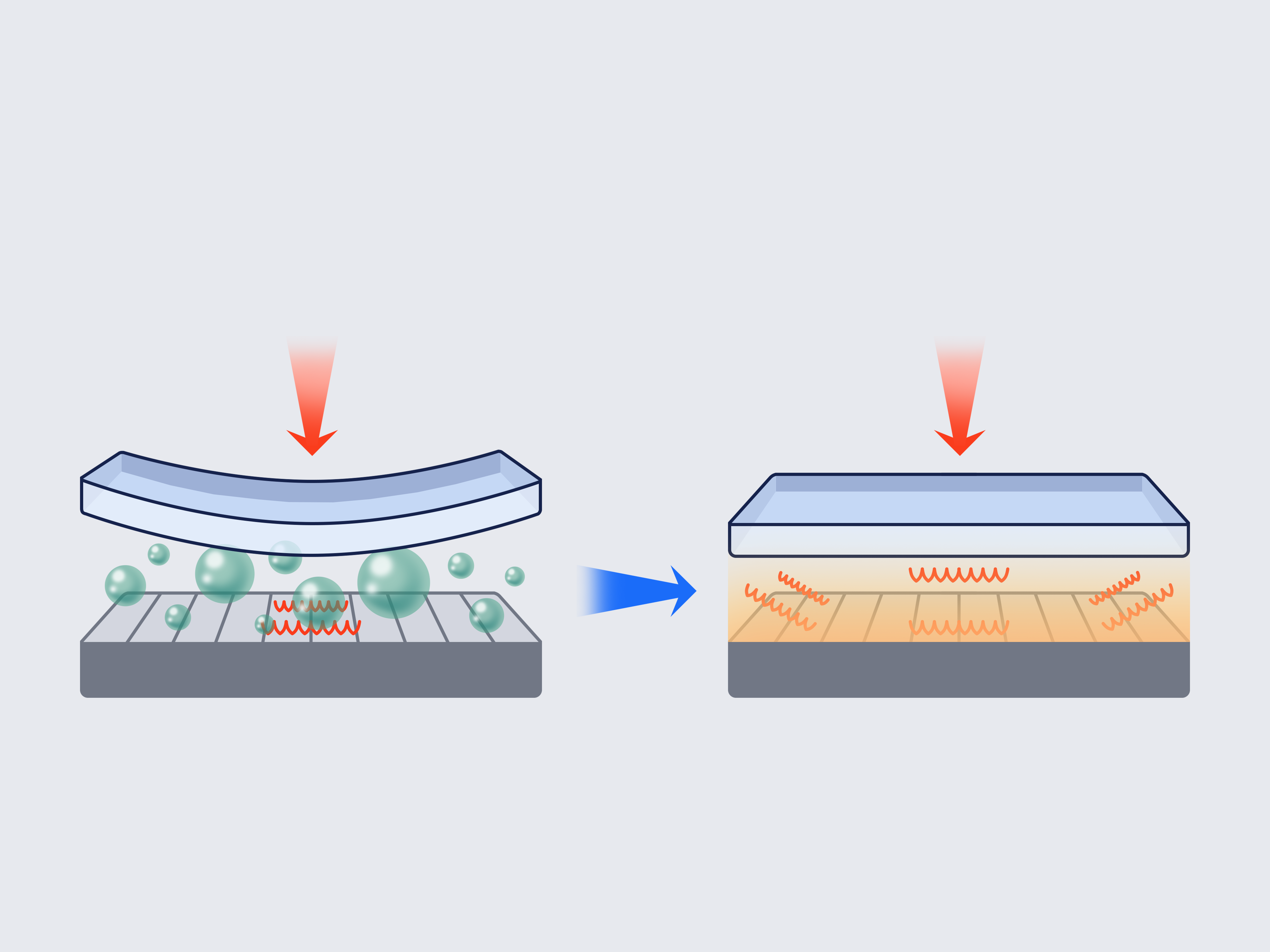

OCA uses a pre-formed adhesive film that is carefully aligned and pressed between the LCD and cover layer. This method provides excellent optical clarity, consistent thickness, and is ideal for high-volume production. It requires precise alignment and is most suitable for standard-sized displays.

OCR, in contrast, uses a liquid resin that is dispensed between the layers and then cured with UV light or heat. Because the resin flows into every gap, it ensures strong adhesion and reduces the risk of bubbles. This makes OCR well-suited for larger or irregularly shaped displays, as well as curved surfaces. The process is more complex, requiring careful control to avoid shrinkage, overflow, or waste during curing, but it delivers exceptional durability.

The choice between OCA and OCR depends on display size, shape, production scale, and performance requirements. Slim, high-volume consumer devices often favor OCA, while OCR is more common in larger and more robust designs. At Beetronics we apply both OCA and OCR in our high-brightness displays, with the optimal technique depending on display size. Compared to other bonding methods, these techniques are the best option for combining outdoor readability, protection against dust and moisture ingress, and a rugged, reinforced structure, making them the best option for demanding professional applications.

Why Optical Bonding Stands Out

Optical bonding provides a range of benefits that go beyond what air gap or tape bonding can deliver.

Improved Readability

By eliminating the air gap, internal reflections are reduced to a minimum. More light passes through the display, resulting in sharper contrast, reduced glare, and a much clearer image in all lighting conditions.

Increased Durability

The adhesive layer reinforces the connection between LCD and cover, creating a more rigid structure. This makes the display significantly more resistant to shock, vibration, and mechanical stress over time.

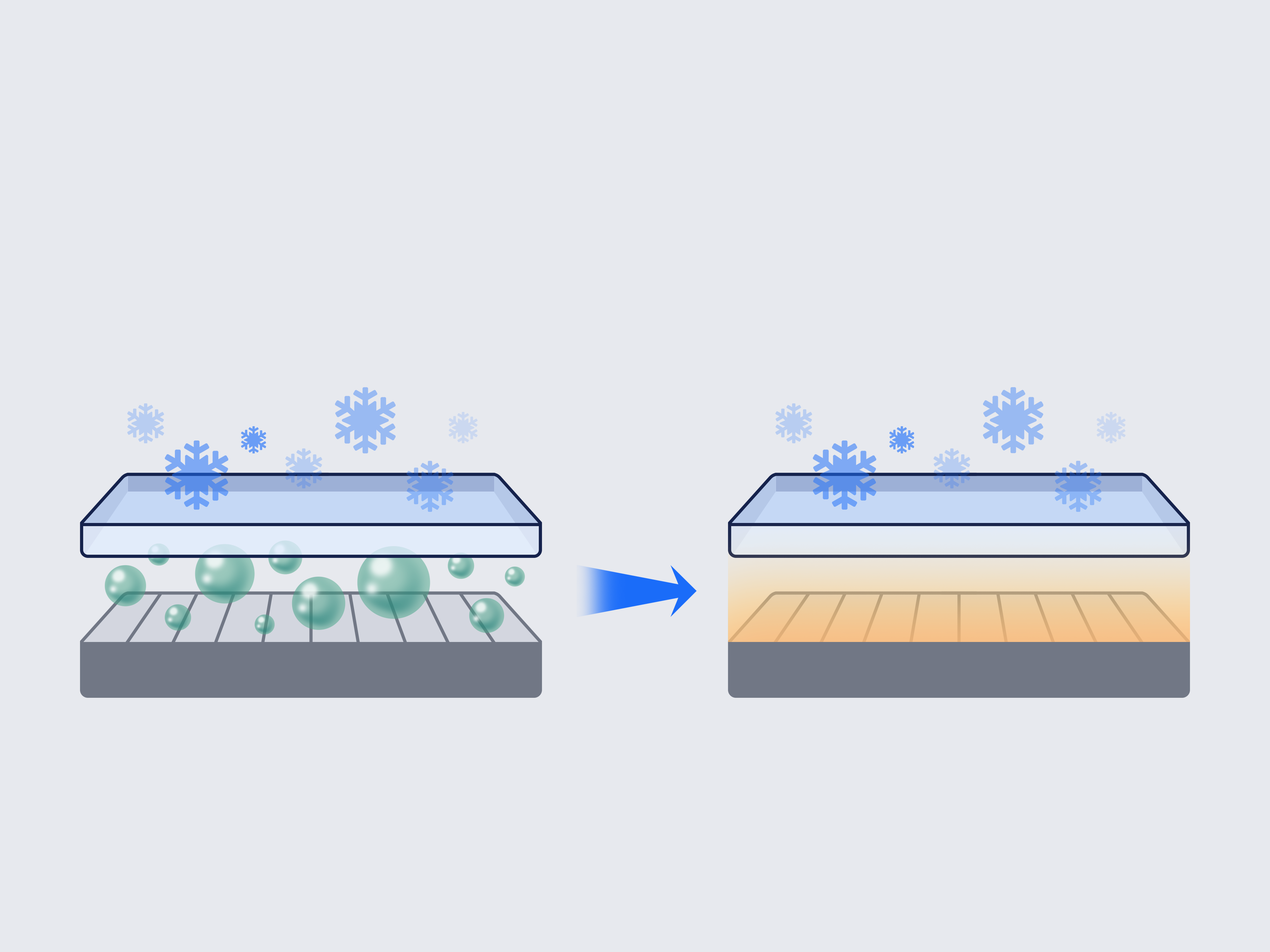

Enhanced Protection Against Dust and Moisture

Because there is no empty space between the layers, there is no room for dust or condensation to enter. This improves reliability and prevents the visual defects often seen in non-bonded displays.

Better Touch Experience

Without a gap, touch input is more direct and precise. The response feels faster, smoother, and more natural, improving the overall user interaction.

Long-Term Reliability

Optical bonding reduces the risk of optical degradation over time. Problems such as delamination, fogging, or discoloration are far less likely, ensuring stable performance and image quality throughout the product’s lifetime.

Limitations and Considerations

Despite its clear advantages, optical bonding is not without challenges. The process is more costly and complex than air gap or tape bonding, and once layers are bonded, repairs are so difficult that they are generally considered commercially unfeasible. Many variables influence the process, and even small defects such as bubbles, misalignment, or uneven curing can lead to waste and lower production yields. Adhesives themselves must also be carefully selected, as poor formulations can yellow under UV exposure or lose stability under extreme temperature and humidity.

The Role of Bonding in Display Selection

Bonding may not be the first thing people think of when evaluating a display, but it plays a decisive role in how a screen performs over its lifetime. Choosing the right method is therefore a critical design decision, ensuring that the display continues to deliver consistent performance in the environment where it is used. Broadly speaking, air gap and tape bonding are sufficient for cost-sensitive products and remain the most common choice. In more demanding conditions where durability, clarity, and long-term reliability matter, optical bonding has become the near-universal standard.

Want to learn more about bonding or explore which display solution best fits your environment? Our specialists are happy to guide you through the options and answer any questions about Beetronics touchscreens displays.