This rapid progression makes it harder than ever to separate genuine breakthroughs from incremental improvements, or even from clever marketing presented as innovation. In this article we bring everything together and take a closer look at the foundations of modern display technology, helping you make sense of how displays work today and where the industry is heading.

From Tubes to Flat Panels

Display technology began with cathode ray tubes (CRT). You may still remember these large, heavy housings from early televisions and monitors. CRTs worked by firing electron beams onto a phosphor-coated surface, producing images with rich colors and deep blacks. They defined television and computer displays for decades. But they were bulky, power-hungry, and inefficient. As demand grew for thinner and lighter screens, CRTs quickly gave way to new technologies, and were gradually replaced by plasma and LCD.

Plasma displays represented the first generation of true flat panels. Each pixel was a tiny gas-filled cell that emitted ultraviolet light when charged, which then excited phosphors to create visible colors. Plasma delivered large screen sizes, smooth motion, and higher contrast than early LCD. But it consumed a lot of power, suffered from burn-in, and was expensive to manufacture at scale. By the early 2010s, plasma had disappeared from the market, leaving LCD as the new standard.

Understanding Transmissive LCD Displays

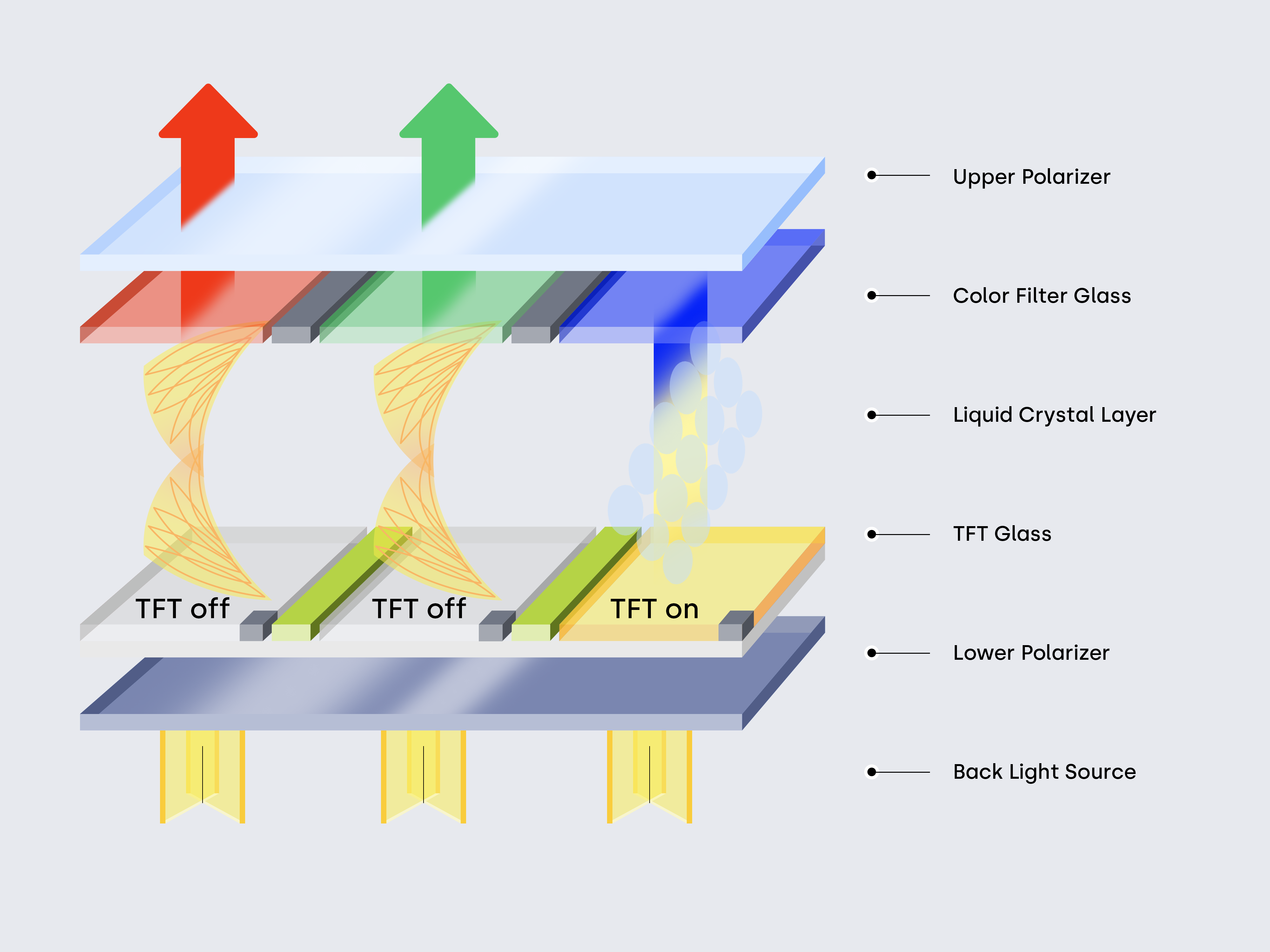

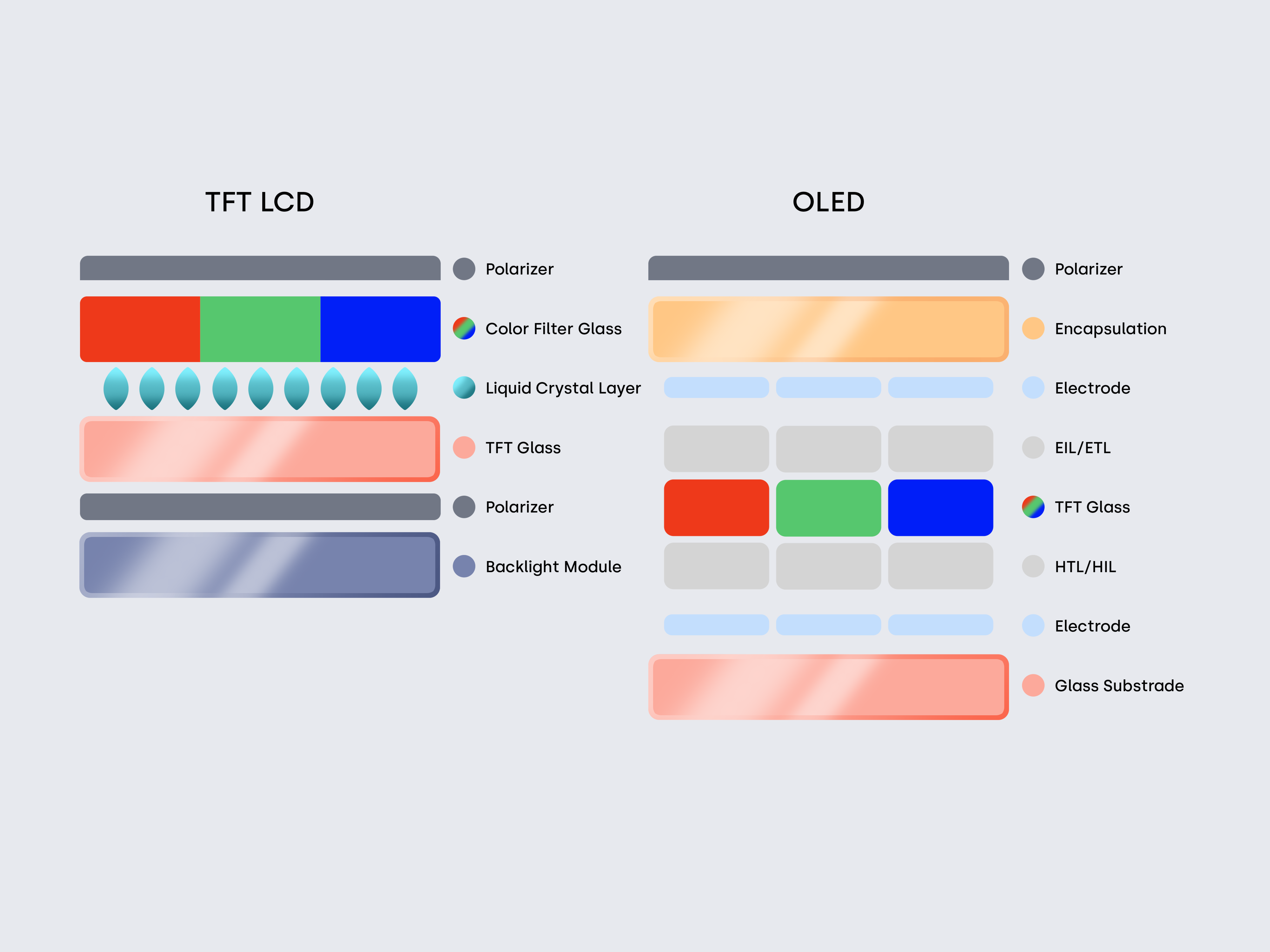

To understand modern flat panels, it is essential to distinguish between transmissive and emissive displays. In emissive systems, pixels generate their own light. In transmissive systems, pixels do not emit light on their own but instead rely on a backlight that shines through layers which control how much light passes through each pixel.

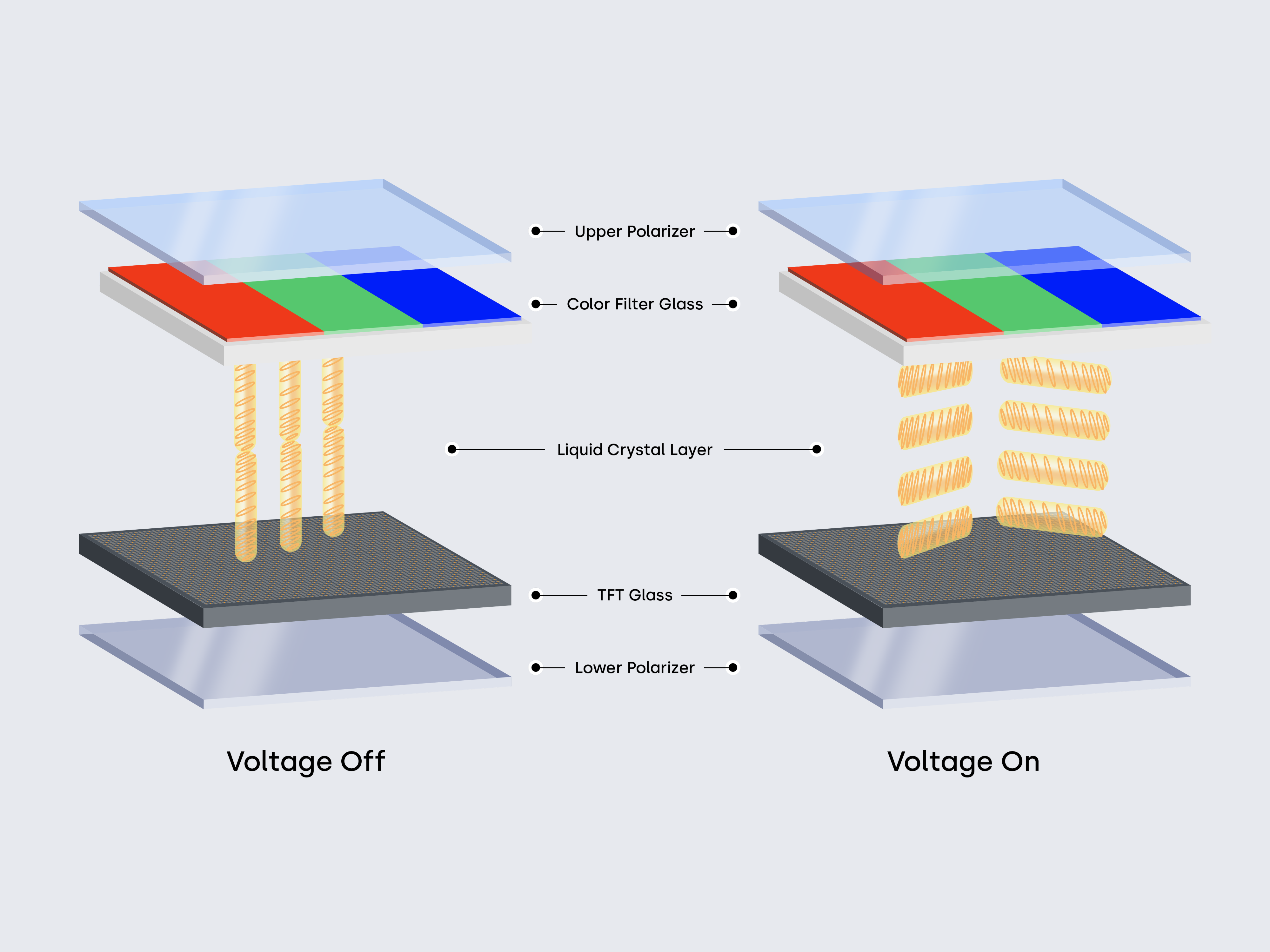

The most widely used transmissive technology is the liquid crystal display (LCD). LCDs remain popular because they provide a strong balance between image quality, reliability, and cost. In an LCD, liquid crystal molecules are sandwiched between two glass substrates, and these substrates are each covered with a polarizer on the outside. When voltage is applied, the electric field makes the molecules reorient, and in combination with the polarizers, this controls how much light passes through. With the addition of color filters, this process creates the final image.

The performance of LCDs is mainly determined by two factors: how the crystals are aligned and how the backlight is designed.

LCD Alignment Modes

Within LCD technology, not all panels behave the same. The way the liquid crystals are arranged directly affects contrast, color accuracy, and viewing angles, which has led to three dominant subtypes.

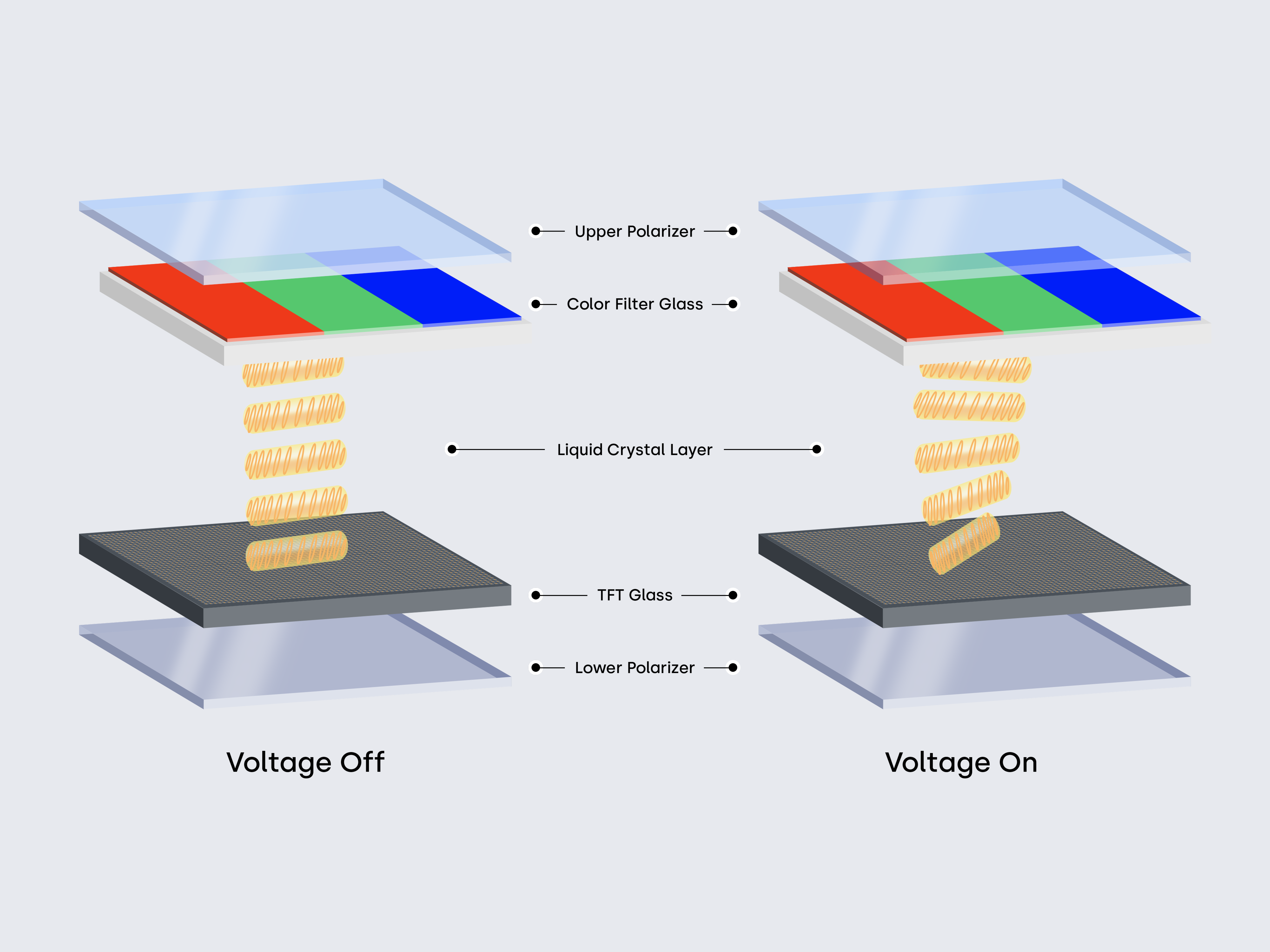

Twisted Nematic (TN) panels twist the crystals up to ninety degrees to control light. They are inexpensive to manufacture and provide very fast response times, but the downsides are narrow viewing angles, visible gamma shift, and limited color accuracy.

Vertical Alignment (VA) panels keep crystals upright in the off state and tilt them when voltage is applied. This allows for higher native contrast and deeper blacks compared to TN. However, response times are slower, and the optimal viewing angles are more limited.

In-Plane Switching (IPS) panels rotate crystals parallel to the substrate. This keeps brightness and color consistent across wide viewing angles and provides accurate reproduction over time. IPS is more costly to produce, but it has become the benchmark for color accuracy, stability, and long-term reliability. This is also why we choose to use IPS panels in all Beetronics monitors and touchscreens. The technology may not deliver the absolute highest contrast or deepest blacks, but it provides the most dependable balance of consistency, durability, and long-term performance while maintaining image quality. That balance is crucial in professional environments where displays need to run reliably day after day, year after year.

LCD Backlighting Systems

Because LCDs are transmissive, the backlight is just as critical as the liquid crystal layer itself. It determines brightness, uniformity, and contrast. Early LCDs used fluorescent lamps, but modern designs rely on LED-based backlights. Even within LED systems, there are important differences.

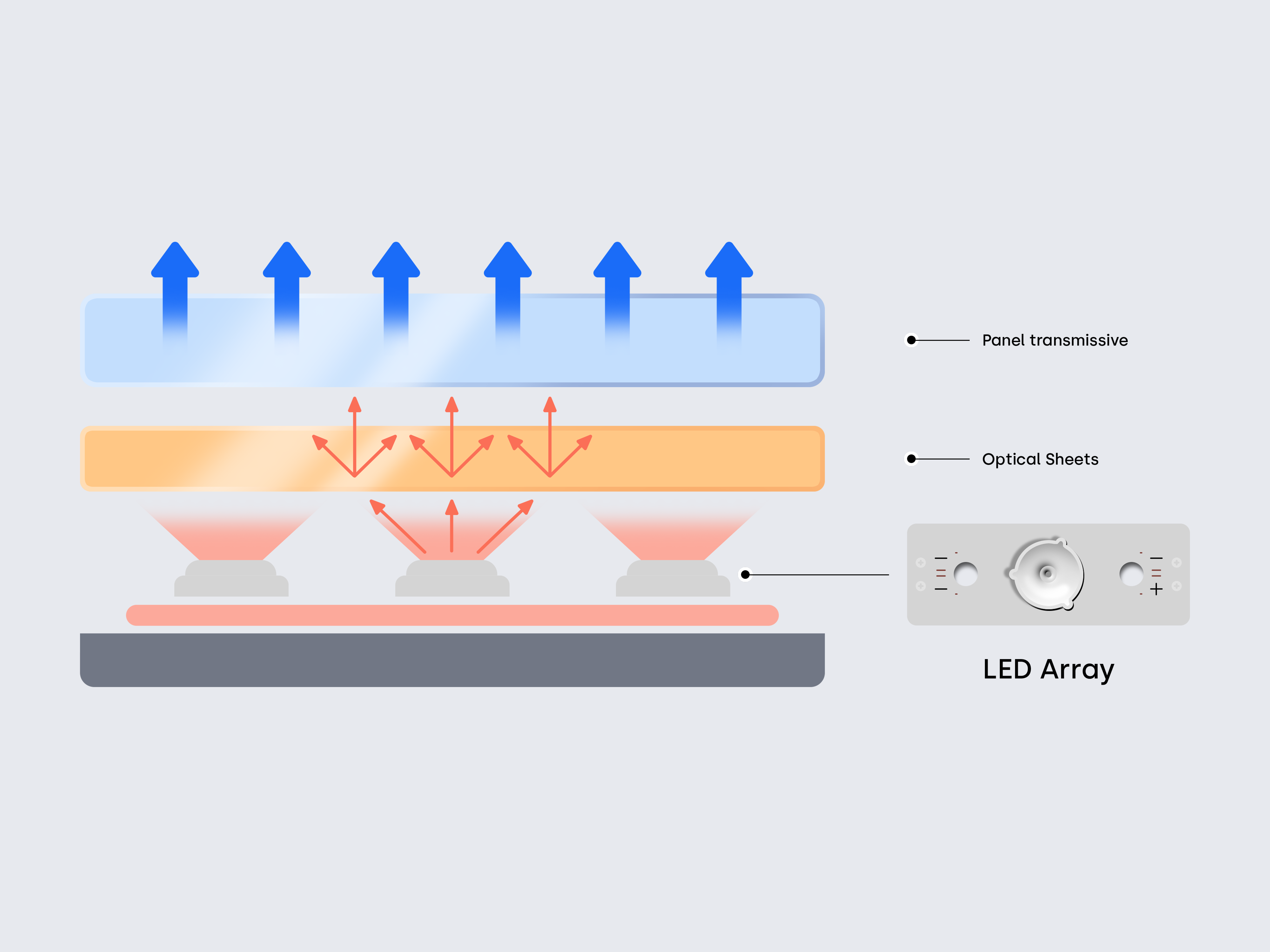

Edge-lit systems place LEDs along the edges of the display and use diffusers to spread the light across the panel. This design makes thinner displays possible but can lead to uneven brightness.

Direct-lit systems distribute LEDs across the back of the display, providing better uniformity. This setup also enables local dimming, where different zones of the backlight can be controlled independently to improve contrast.

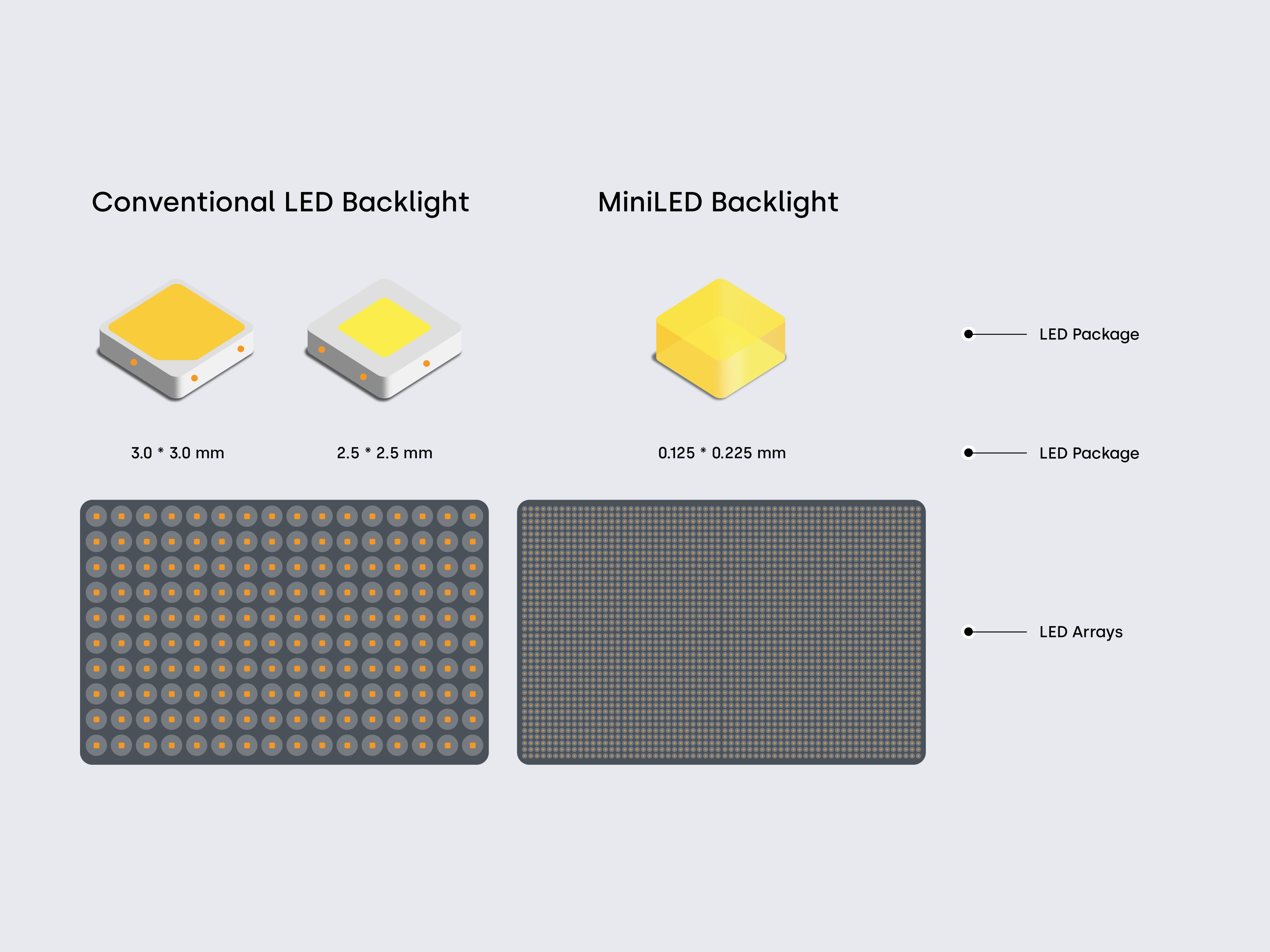

The most advanced step in backlighting is MiniLED. By shrinking LED packages below two hundred micrometers, manufacturers can place thousands of LEDs behind the display. This allows for very fine-grained local dimming, delivering much higher peak brightness and much better contrast precision than conventional LED backlights. MiniLED panels can achieve brightness levels above one thousand nits, but the complexity and production cost of the technology are significantly higher.

Recent LCD Enhancements

Beyond alignment and backlighting, additional layers of innovation have been added to LCD to push performance even further. The most notable is Quantum Dot enhancement.

Quantum Dots are semiconductor nanocrystals that emit highly pure colors when exposed to light. By inserting a Quantum Dot layer between the backlight and the LCD panel, manufacturers achieve a wider color gamut, improved efficiency, and stronger color accuracy.

Today, Quantum Dot is most commonly used as an enhancement film paired with blue LED backlights. While research is underway into electroluminescent Quantum Dots that could one day act as light emitters themselves, for now Quantum Dot remains just an enhancement of LCD rather than a standalone display technology.

The Rise of Emissive Displays

While LCDs shape and filter light from a backlight, emissive displays take a completely different approach. In these systems, every pixel is its own light source, eliminating the need for a separate backlight. This fundamental change enables deeper blacks, faster response, and entirely new design possibilities.

Organic light emitting diodes (OLED) (OLED is emissive) rely on organic compounds that emit light when voltage is applied. Each pixel produces its own red, green, or blue light, enabling true blacks, infinite contrast ratios, ultra-fast response times, and displays that are thin, lightweight, and even flexible. Variants such as AMOLED and Micro-OLED bring the same principle to different formats, from smartphones to head-mounted devices.

OLED isn’t without its trade-offs. Because the pixels are made from organic materials, they gradually degrade with blue subpixels that tend to fade the fastest. If you leave a static image on too long, you risk permanent burn-in. Compared to LCD panels with MiniLED backlights, OLED also can’t hit the same peak brightness levels. And while the picture quality is stunning, producing large OLED panels is still expensive due to lower manufacturing yields. In short, OLED delivers incredible visuals, but it’s not the best choice for situations where long-term reliability and durability are top priorities.

MicroLED takes emissive technology further. Instead of organic compounds, each pixel is a microscopic inorganic LED capable of emitting its own light. MicroLED combines the benefits of OLED with much higher durability, efficiency, and no risk of burn-in. It can achieve very high brightness and scale to very large or unconventional display shapes. The challenge lies in manufacturing. Aligning and transferring millions of micro-LEDs with high precision is one of the most complex problems in electronics production today. Costs remain very high, which means MicroLED is currently limited to niche and luxury applications. Still, it is widely seen as the most promising long-term successor to both LCD and OLED, provided the manufacturing hurdles can be overcome.

A Unique E-Ink Alternative

Alongside transmissive and emissive technologies, there is also a reflective approach that works on entirely different principles. Electrophoretic displays, better known as E-Ink, rearrange charged black and white particles inside microcapsules to reflect ambient light, creating an image that looks like ink on paper.

E-Ink’s strengths are paper-like readability in sunlight and extremely low power consumption, since energy is only needed when the image changes. Its limitations are slow refresh rates and limited color reproduction. For specialized uses such as e-readers and signage, however, E-Ink demonstrates how radically different display concepts can succeed alongside mainstream technologies.

The State of Display Technology Today

There is no single display technology that stands above all others. Each comes with its own balance of cost, performance, longevity, and manufacturing complexity. By understanding these trade-offs, it becomes easier to look past marketing claims and understand the real forces that drive progress in display design.

LCD remains the backbone of the display industry thanks to its versatility and affordability, while innovations within this segment like IPS alignment, MiniLED backlighting, and Quantum Dot technology keep it competitive and up to date. OLED has set the benchmark for image quality but continues to face limits in lifetime and brightness. MicroLED is widely regarded as the long-term successor to both, though mass production remains the obstacle. And technologies like E-Ink remind us that entirely different approaches can thrive where efficiency or readability matter more than color or motion.

Curious which display technology is right for you? Our specialists are ready to guide you through the options, help determine the best fit for your project, and answer any questions you may have.